DESIGN MECHANISM AND PROTOTYPING

Beyond fabrication, we provide engineering-driven design and prototyping services for clients who need functional, reliable, and production-ready solutions. We support projects that involve movement, load, precision, integration of components, and real-world constraints.

Our approach bridges the gap between concept and manufacturable reality.

Engineering-Led Design Approach

We begin by understanding the functional goal of the system rather than just its appearance.

Functional requirement analysis

Motion, load, and interaction definition

Space constraints, tolerances, and assembly logic

Selection of materials, mechanisms, and standard components

Every design decision is made with manufacturability, durability, and maintenance in mind.

Mechanism & System Design

We design and engineer custom mechanical systems tailored to your application.

Moving assemblies, linkages, sliding and rotating mechanisms

Hinges, lifts, foldable structures, and concealed motion systems

Integration of motors, linear actuators, bearings, and guides

Structural frames and internal reinforcements

Whether the goal is smooth motion, compact packaging, or high load capacity, we engineer mechanisms that perform reliably under real conditions.

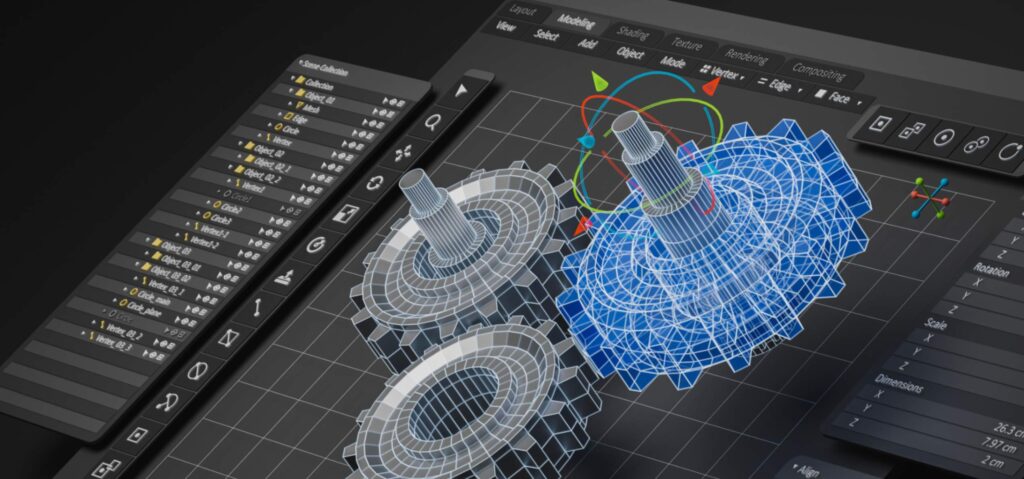

3D Modeling & Technical Documentation

All designs are developed using professional CAD tools and engineering workflows.

Detailed 3D models and assemblies

Interference checks and motion simulations

Engineering drawings for fabrication and assembly

CNC-ready and prototype-ready files

This ensures clarity, repeatability, and smooth communication between design, fabrication, and installation.

Prototyping & Functional Testing

We build physical prototypes to validate design intent before final production.

Rapid prototyping using CNC machining, laser cutting, and 3D printing

Assembly and fit verification

Functional testing of motion, load, and durability

Iterative refinement based on test results

Prototyping reduces risk, saves cost, and allows informed decision-making before scaling or final fabrication.

Integration with Fabrication & Installation

Because engineering and fabrication are handled in-house, we ensure that designs transition seamlessly into production.

Design optimized for CNC and laser processes

Assembly-friendly designs for fast installation

Coordination between mechanical, electrical, and finishing systems

Support during fabrication and on-site implementation

This integrated workflow eliminates disconnects between design intent and real-world execution.

Who This Service Is For

Our engineering and prototyping services are ideal for:

Exhibition and event installations with moving or interactive elements

Custom display systems and product showcases

One-off mechanisms and proof-of-concept builds

Clients developing new products or custom systems

Designers and agencies needing engineering support

Why Work With Us

Engineering-focused thinking, not trial-and-error

Strong background in fabrication and real-world constraints

Fast prototyping and iteration cycles

Clear documentation and production-ready outputs

We don’t just design how things look — we design how they work.